FAT PRJ000176-ENG-DRA-132 Recovery Tool.docx

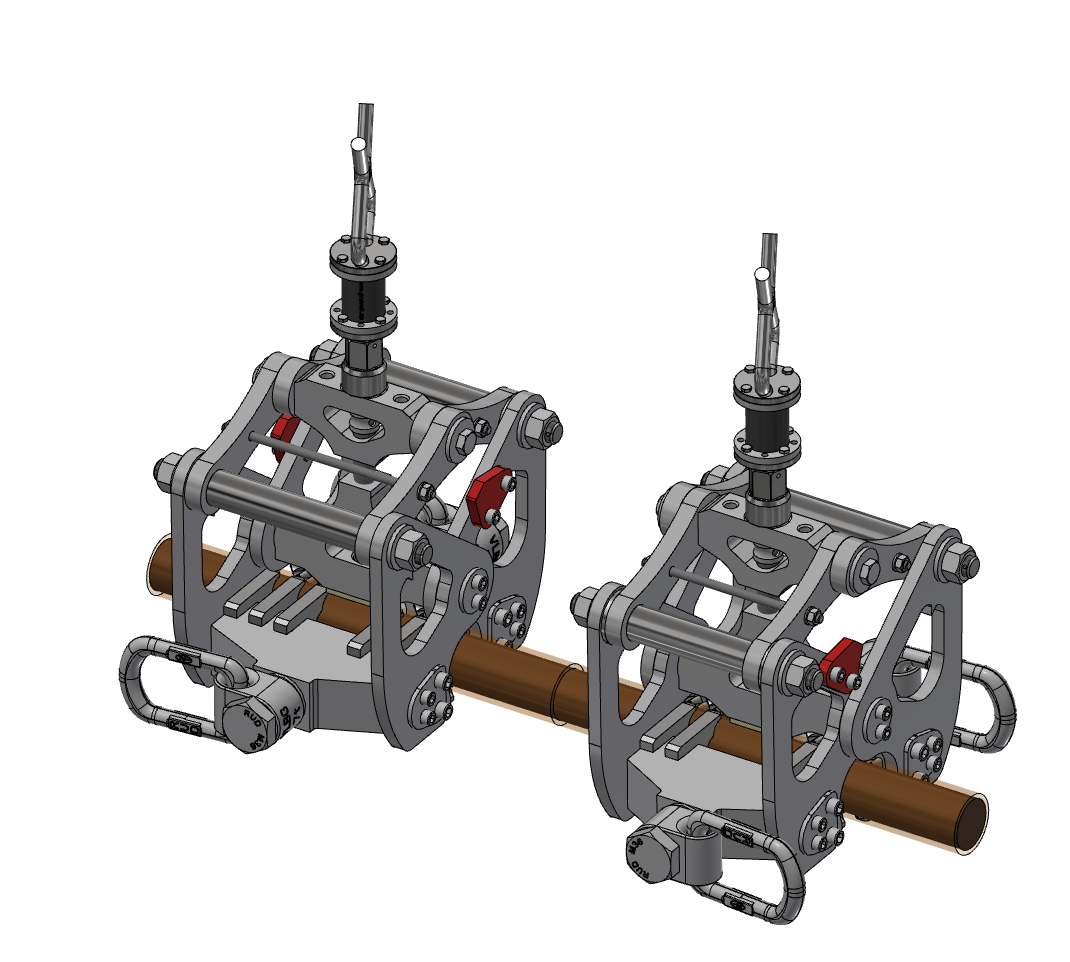

2 off Recovery tools are fabricated by Remotion for the SLM DEH project (PRJ000176)

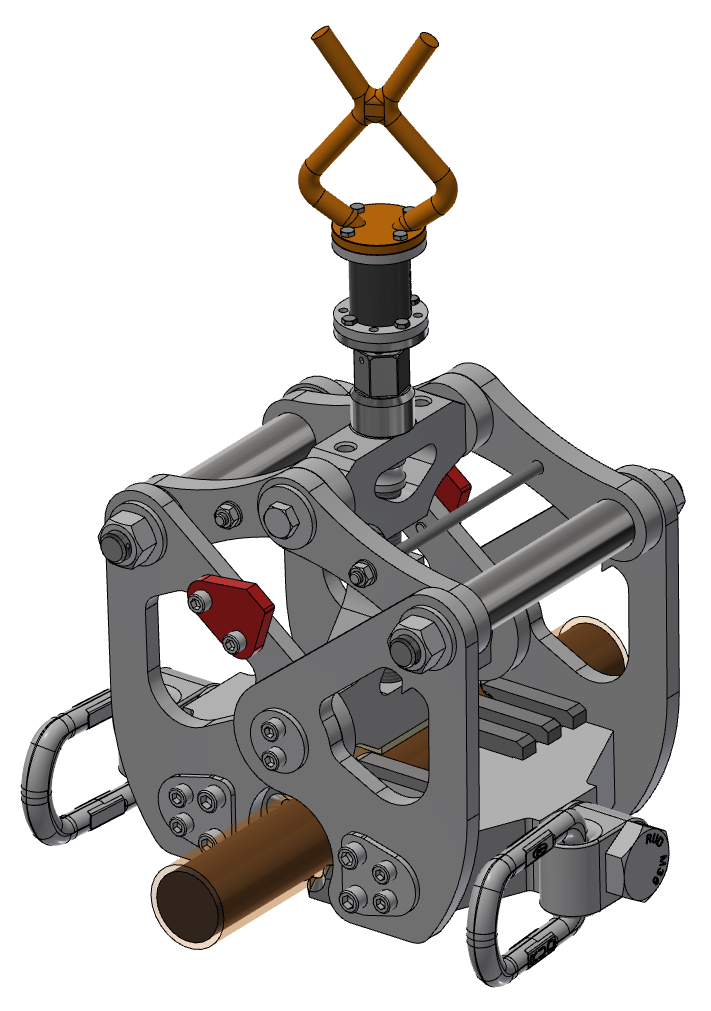

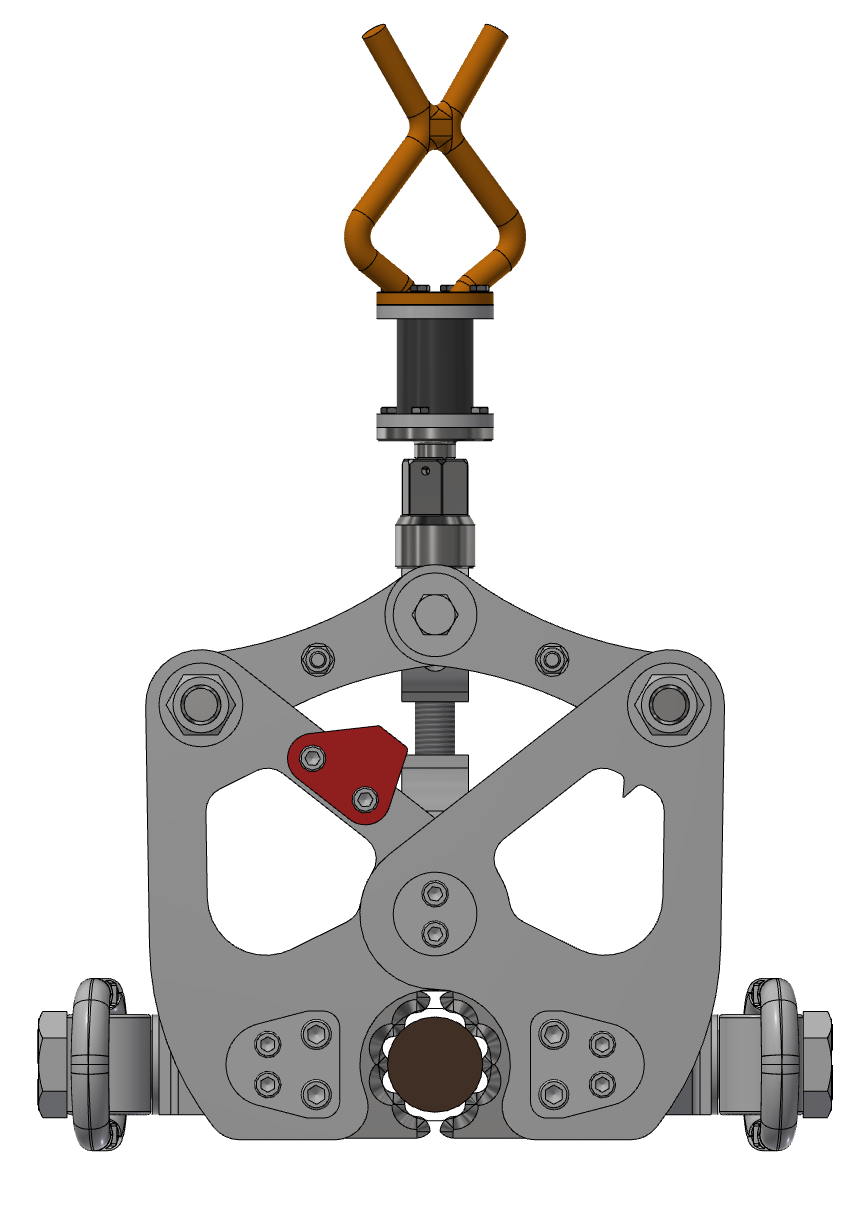

The scissor concept Recovery Tool is lowered on the cable and closed, making contact with the cable with ten jaws, dimensioned to interact with the armor layer/copper conductor of the cable. The WLL of the tool is 6 Te, so the lifting test will be performed with 12 Te load, with two clamps holding onto the two ends of one test piece.

All operations shall be conducted in a safe manner for equipment and personnel. It is the responsibility of the Test Supervisor to ensure that a formal safety briefing is given prior to any work commencing.

In addition to the “standard” safety requirements, the following safety points shall be observed during all assembly and commissioning task:

- The test area shall be fenced off during load testing activities.

- Only authorized personnel should have access.

- Safety information and SJA to be performed before start of activity.

- Appropriate PPE to be used.

- When lifting equipment during assembly and handling work, the personnel shall use the dedicated equipment and ensure that all slings, shackles, etc. have valid test certificates. If any doubt, contact the responsible Test Supervisor.

- Ø74 mm Piggy-back cabel test piece

- Approx. Ø65 mm Aluminium test piece to emulate feeder cable outer armor OD.

- Torque wrench 200Nm

- Install clamps on test piece

- Slings mounted in VLGB M36 RUD

- Attach rigging from each clamp to the ends of the test bench.

Take pictures for all task below.

|

|

Task |

Results/Remarks |

Comments/Sign |

|

1 |

Verify assembly and function. Check main bolt lubrication. |

|

|

|

2 |

Check for sharp edges for personnel handling the clamp. |

|

|

|

3 |

Check ROV interface; Check TT adapter interface. |

|

|

|

4 |

All insert sizes fit the recovery tool. |

|

|

|

5 |

Verify test piece diameter. |

|

|

|

6 |

Certificate from Load Test SWL 12Te |

|

|

|

7 |

Rov Handles |

|

|

|

8 |

RUD VLBG torqued to 700Nm. |

|

|

|

|

|

|

|

|

|

Task |

Results/Remarks |

Comments/Sign |

|

9 |

Install clamp on test piece, torque hex bolt to 10 Nm with a manual torque wrench. Verify jaw fit on test piece once fully torqued. |

|

|

|

10 |

Attach 4x VLBG Rud Lifting eye to test bench. |

|

|

|

11 |

Pull test assembly to 12 Te. Hold for 5 minutes. |

|

|

|

12 |

Inspect for damage. If no damage is observed: stop test and inspect clamp. |

|

|

|

13 |

Attempt to repeat steps 9-12 using the aluminium dummy piece. |

|

|

Appendix 1: Drawing, PRJ000176-ENG-DRA-132